Pipe support forms the foundation for achieving operational efficiency in today’s industrial landscape. Every facet of a facility, from raw material intake to finished product delivery, hinges on smooth operation. This translates to a relentless pursuit of optimisation across all areas. Here’s where pipe support shines. By ensuring the secure and proper management of pipes throughout a facility, pipe support systems contribute directly to the three pillars of industrial success:

- Smooth Production: Well-supported pipes experience minimal movement and stress, leading to fewer disruptions in flow and reduced risk of damage. This translates to consistent production schedules and timely delivery of products.

- Reduced Costs: Robust pipe support minimises the need for maintenance and repairs associated with pipe failures, leaks, and spills. It also extends the lifespan of pipes and related equipment, leading to significant cost savings in the long run.

- Enhanced Safety: Secure pipe support prevents pipe movement that could cause accidents or injuries. Additionally, it minimises the risk of leaks and spills, which can pose safety hazards and environmental concerns.

By providing a stable and reliable foundation for your pipe network, pipe support systems are an often overlooked yet crucial element in achieving operational excellence.

What are Pipe Support Systems?

Pipe support systems are a network of elements designed to safely suspend, guide, and restrain pipes within a facility. These systems are essential for various industries, including:

- Oil and Gas

- Chemical Processing

- Power Generation

- Manufacturing

- Construction

The Importance of Effective Pipe Supports

Properly designed and installed support systems offer a multitude of benefits, including:

- Enhanced Safety: Robust supports prevent pipes from sagging, swaying, or vibrating excessively. This minimises the risk of pipe failures, leaks, and spills, which can lead to injuries, environmental damage, and costly downtime.

- Improved Efficiency: Well-supported pipes experience less stress and strain, leading to reduced maintenance requirements and extended equipment lifespan. This translates to lower operational costs and increased productivity.

- Space Optimization: Support systems allow for efficient use of space by enabling pipes to be routed overhead, along walls, or beneath floors. This frees up valuable floor space for other essential equipment or processes.

- Simplified Installation and Maintenance: Modern support systems are designed for ease of installation and maintenance. This minimises downtime during initial setup and future modifications.

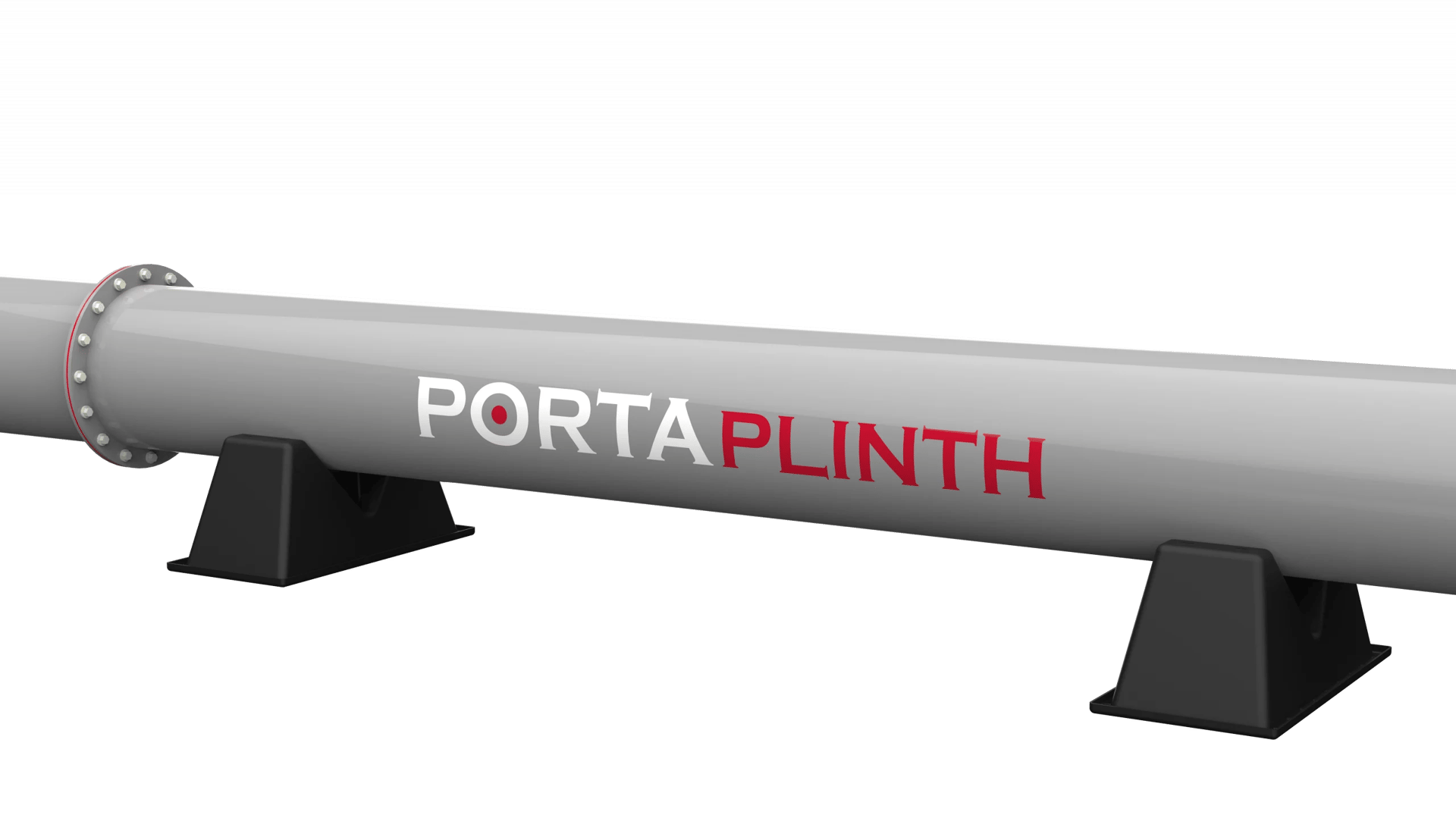

Benefits of Porta Plinth™ Pipe Cradles from TSS Global

TSS Global is proud to offer Porta Plinth™ pipe cradles, a versatile and innovative pipe support solution. Porta Plinth™ cradles are known for their:

- Durability: Manufactured from high-grade materials, Porta Plinth™ cradles can withstand demanding industrial environments.

- Versatility: Available in a wide range of sizes and configurations, Porta Plinth™ cradles can accommodate various pipe diameters and weights.

- Ease of Use: The simple design of Porta Plinth™ cradles allows for quick and easy installation, saving time and labour costs.

- Adjustability: Porta Plinth™ cradles offer superior adjustability, enabling precise pipe alignment and facilitating future modifications.

- Safety: The inherent stability of Porta Plinth™ cradles promotes safety by minimising the risk of pipe movement and related hazards.

| Feature | Benefit |

|---|---|

| Durability | Withstands demanding industrial environments |

| Versatility | Accommodates various pipe diameters and weights |

| Ease of Use | Quick and easy installation |

| Adjustability | Enables precise pipe alignment and facilitates future modifications |

| Safety | Minimises the risk of pipe movement and related hazards |

Choosing the Right Pipe Support Solutions

Selecting the appropriate pipe support system requires careful consideration of several factors, including:

- Pipe size and weight: The support system needs to be able to handle the weight and stress of the pipes it carries.

- Pipe material: Different pipe materials have varying support requirements.

- Operating temperature and pressure: The system must be suitable for the expected temperature and pressure conditions.

- Environmental factors: Consideration should be given to potential exposure to corrosion, vibration, or seismic activity.

- Accessibility: The support system should allow for easy access for maintenance and inspection.

TSS Global: Your Partner for Pipe Support Solutions

TSS Global offers a comprehensive range of pipe support solutions, including Porta Plinth™ cradles, to meet the diverse needs of your facility. Our team of experts can assist you in selecting the most appropriate support system for your specific application, ensuring optimal efficiency, safety, and cost-effectiveness.

Contact TSS Global today to discuss your pipe support requirements and experience the benefits of our innovative solutions.

By partnering with TSS Global for your pipe support needs, you can gain a trusted advisor with the expertise to help you achieve operational excellence.

Contact TSS Global today to learn more about how our pipe support solutions.